About company

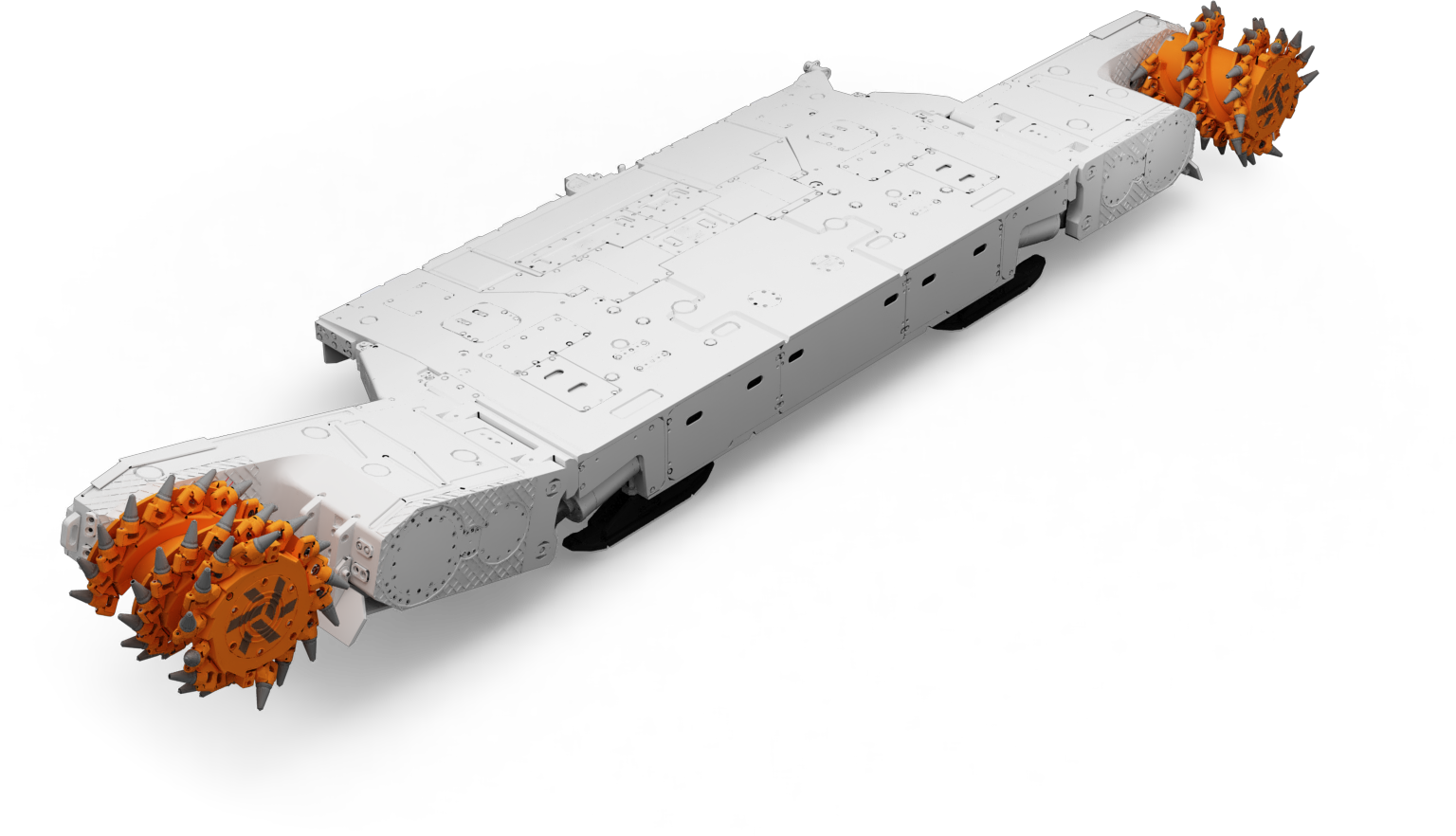

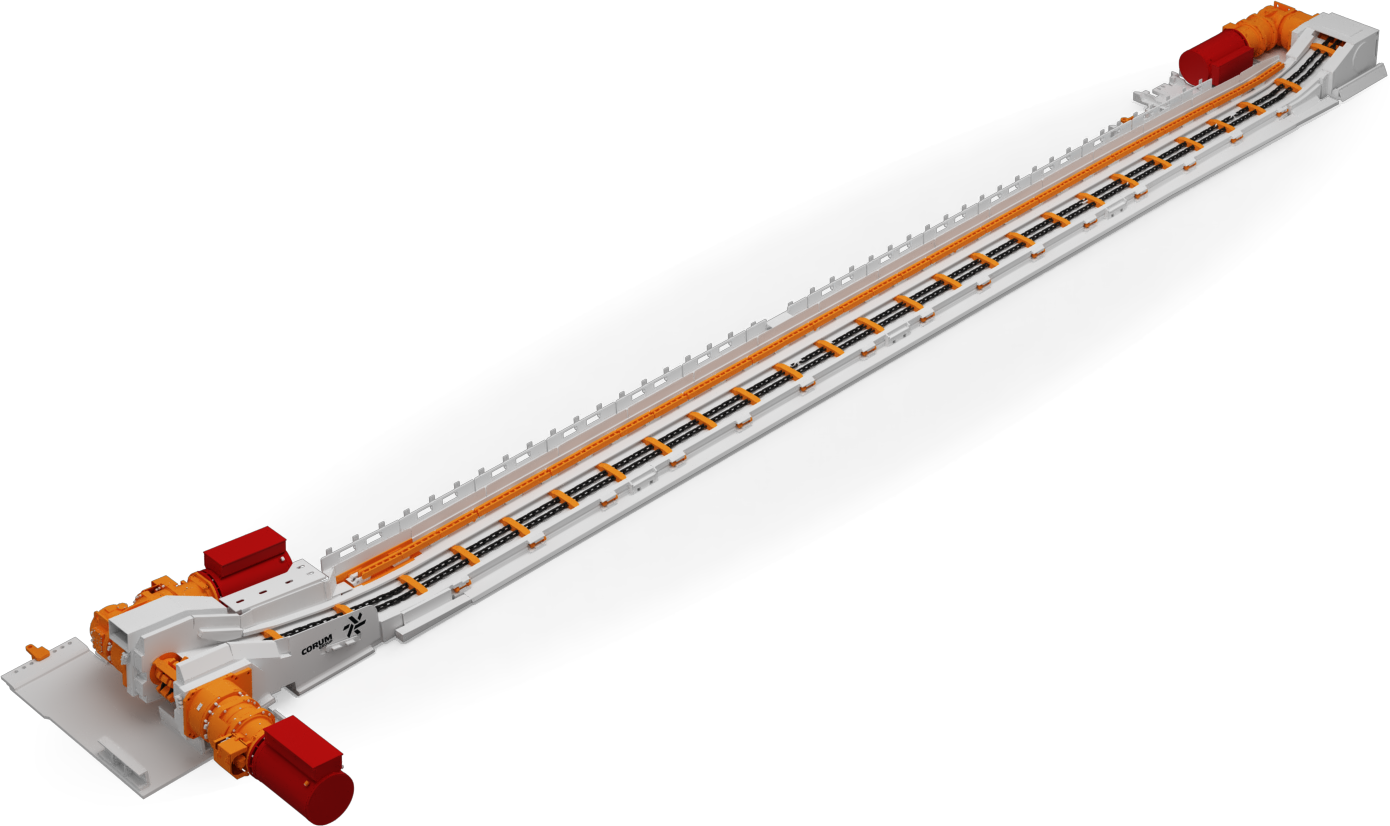

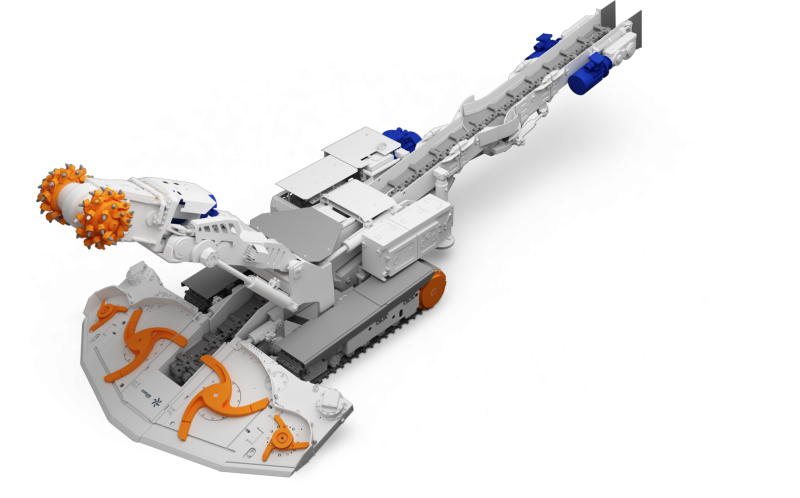

The enterprise produces mining equipment, spare parts, performs repairs and provides service.

Over the past five years, the plant has been able not only to maintain, but also to strengthen its position as a leader in machine building, since it offers high-quality, modern products designed for the unique conditions of each client. Over the past three years, almost 45 thousand new items have appeared in the nomenclature directory of the “Corum Svet Shakhtera” plant. In total, the enterprise manufactures about 200 thousand items of products.

The plant constantly renews the equipment pool with modern high-precision metalworking equipment, introduces new materials and technologies. And a team of thousands professionals of the plant feel secure about their future, having stable orders.

Facebook

Facebook

YouTube

YouTube LinkedIn

LinkedIn E-mail

E-mail