Back

CORUM DRUZHKIVKA MACHINE BUILDING PLANT

About company

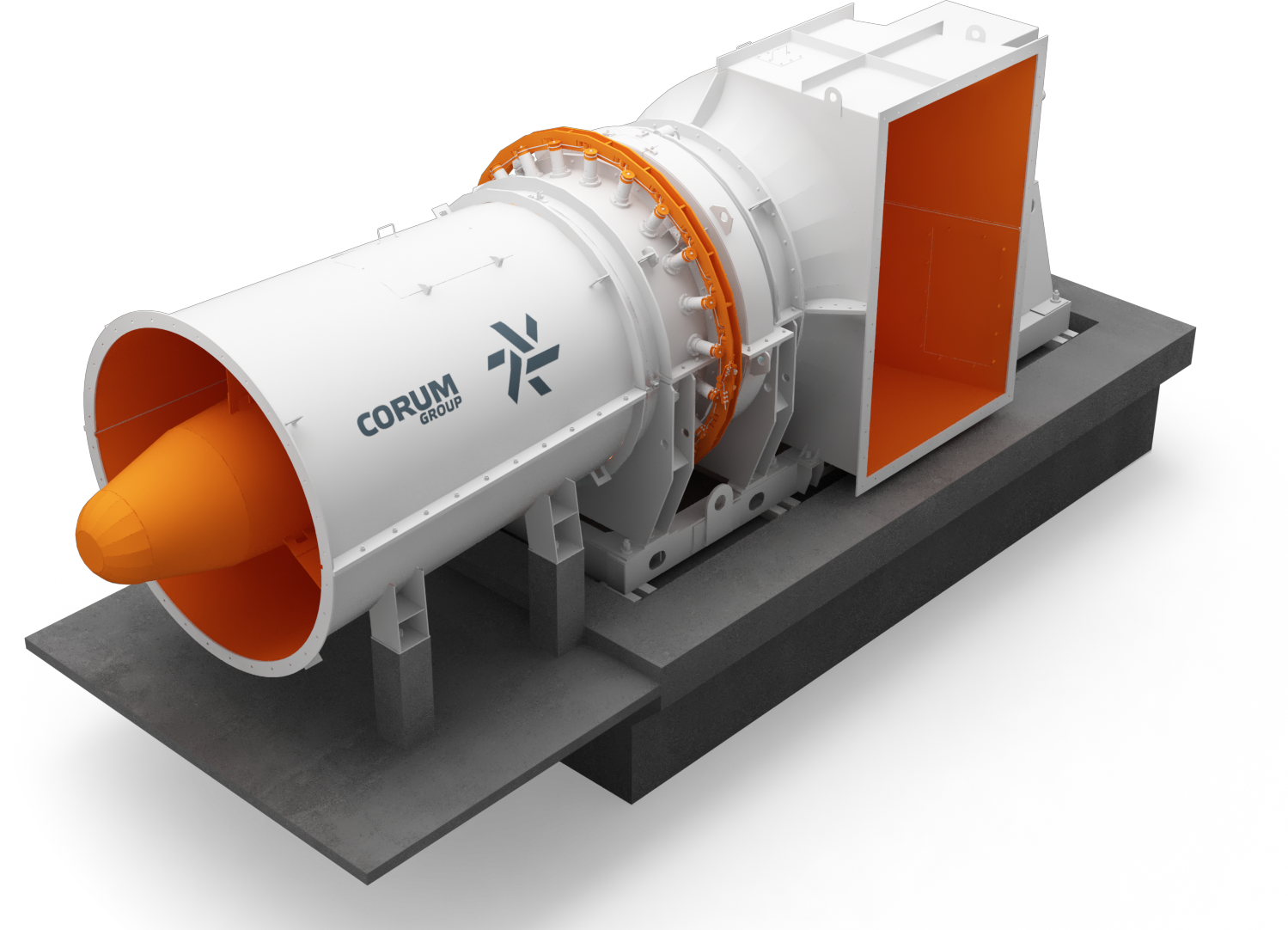

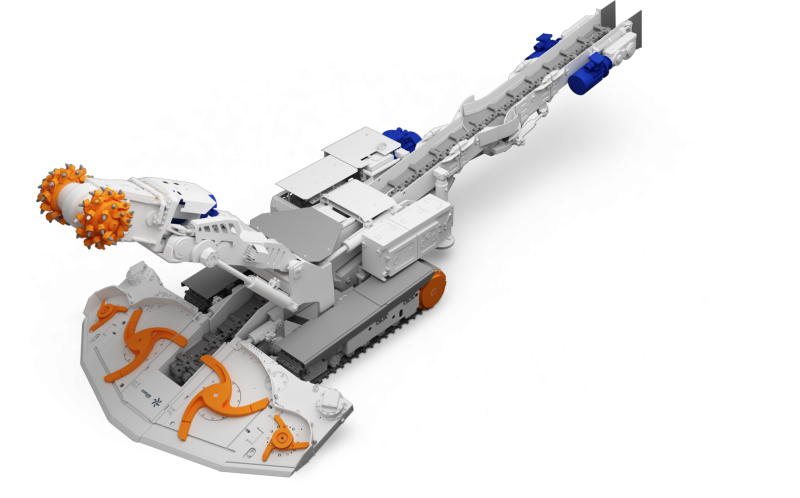

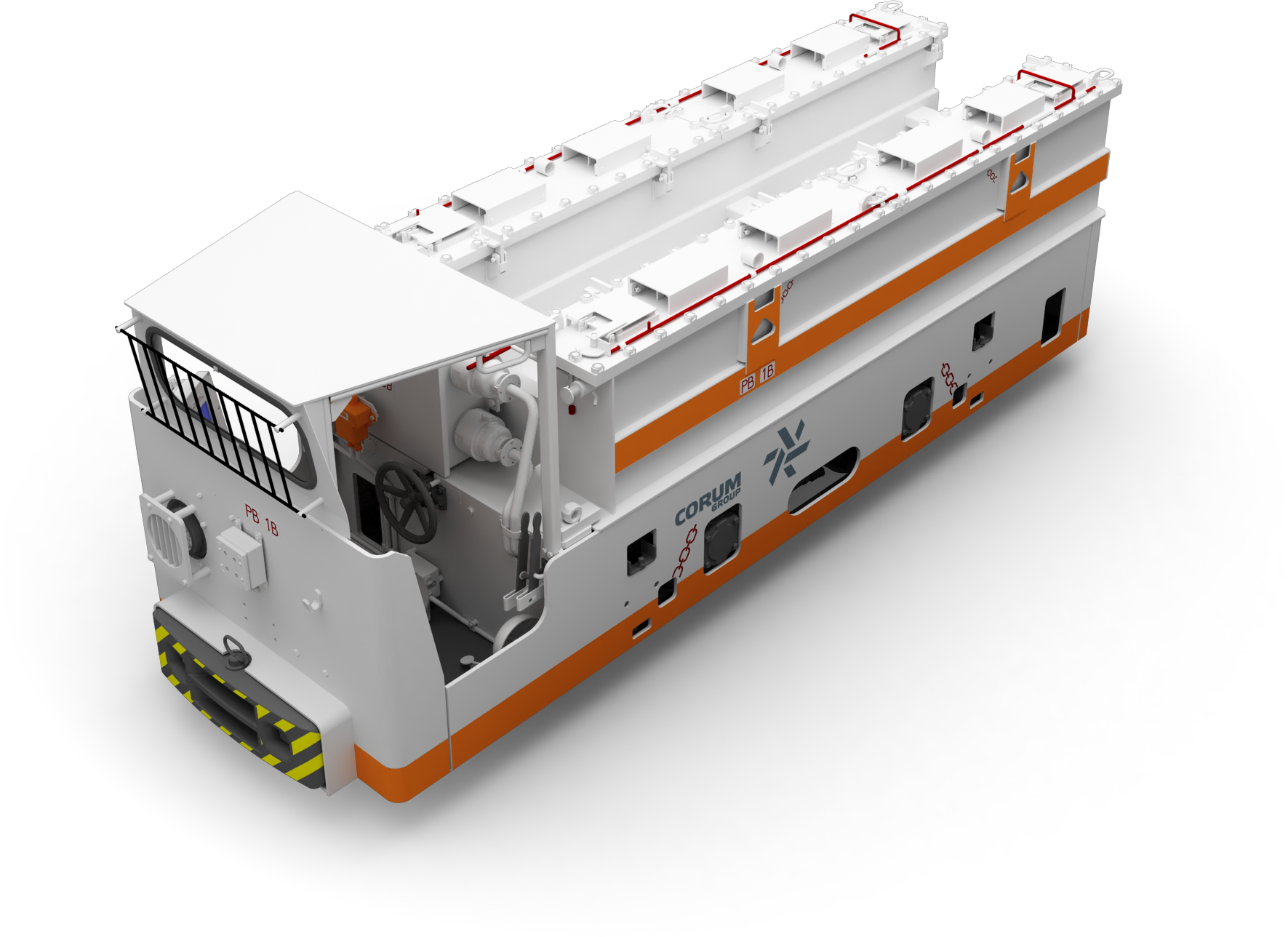

The company was founded in 1893. All started with a small metallurgical plant and hopes for a bright future. Focusing on the customers’ needs, Corum DrM-BP is expanding its product line. Along with the production of supports, trolleys and electric locomotives, the production of suspended mine equipment, main fans, belt conveyors, roadheaders KPD has been mastered by the plant.

The geography of supplies is also expanding - the main consumers are mining enterprises of Ukraine, Poland and others.

Focusing on many years of experience and professionalism, Corum Druzhkivka Machine Building Plant" creates mining equipment, with the help of which customers achieve the highest results in difficult mining and geological conditions.

214,1 th.

214,1 th.

items of product range

17 workshops

17 workshops

are involved in the production of equipment

1,6 th.

1,6 th.

employees working at the plant in Druzhkivka

Milestones in history

1893

The Donetsk Iron and Steel Works of the Donetsk Society of Iron and Steel Production in Druzhkivka was founded.

1894

The first blast furnace appeared.

1896

A rail-rolling department was put into operation, rails become the main products.

1898

The Toretsk steel and mechanical plant was built on the territory of Count Borisov Druzhkivka sugar plant. Began production of equipment for railways: turnouts, springs, etc.

1917

After the coup d'etat, the plants in Druzhkivka were stopped.

1920

On the basis of the plants of the Donetsk and Toretsk societies, a single Toretsk steel and mechanical plant was created, which manufactured equipment for mines and railways.

1925

A trolley shop was built.

1930

Iron foundry and restoration model shops were built.

1941

The plant was evacuated to Aleksandrovsk, Perm region, where it was quickly restored and began production for the needs of the front.

1943

The plant was officially declared an operating enterprise after restoration at its former location in the city of Druzhkivka.

1945

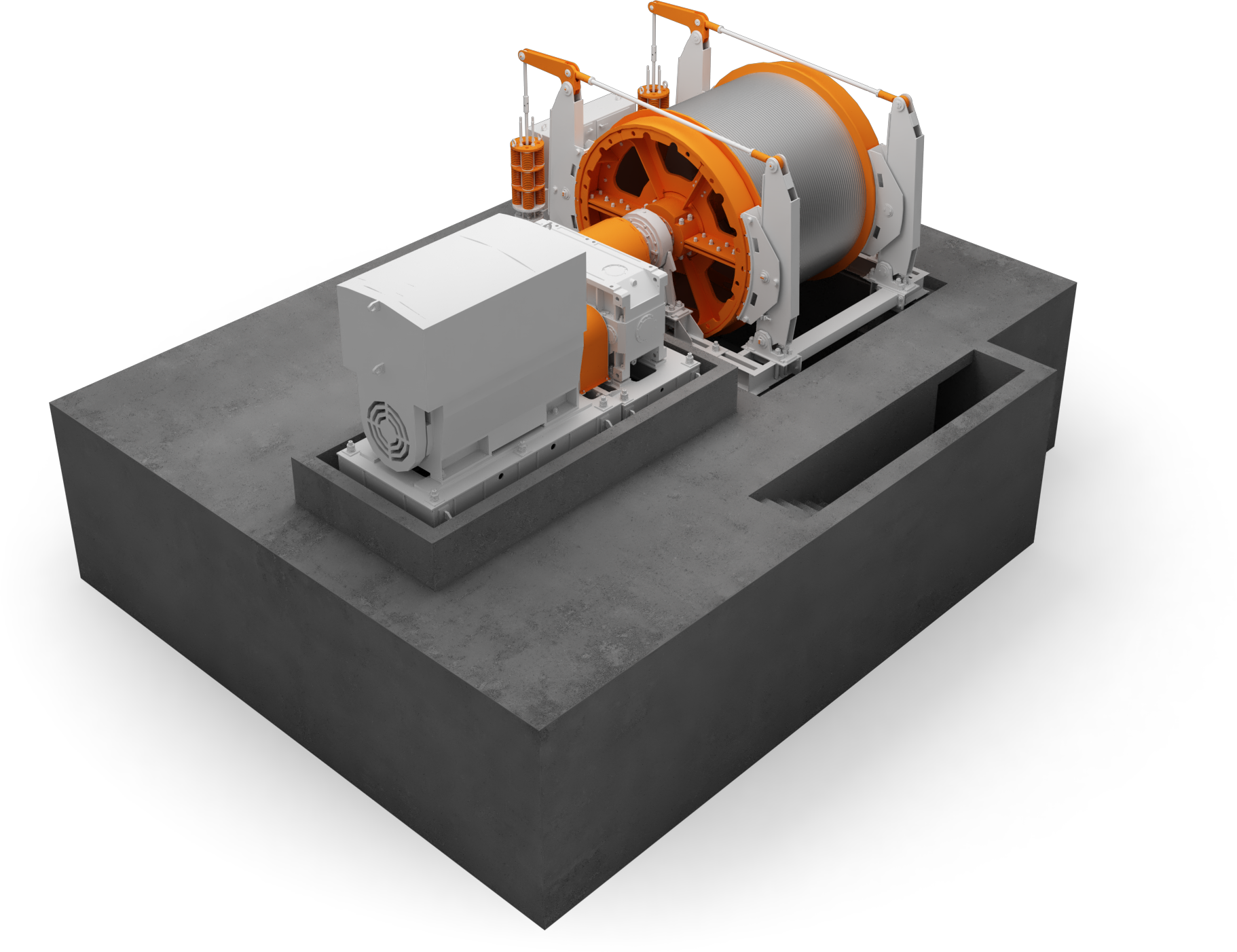

Start of production of winches and winders for mines.

late 1950s

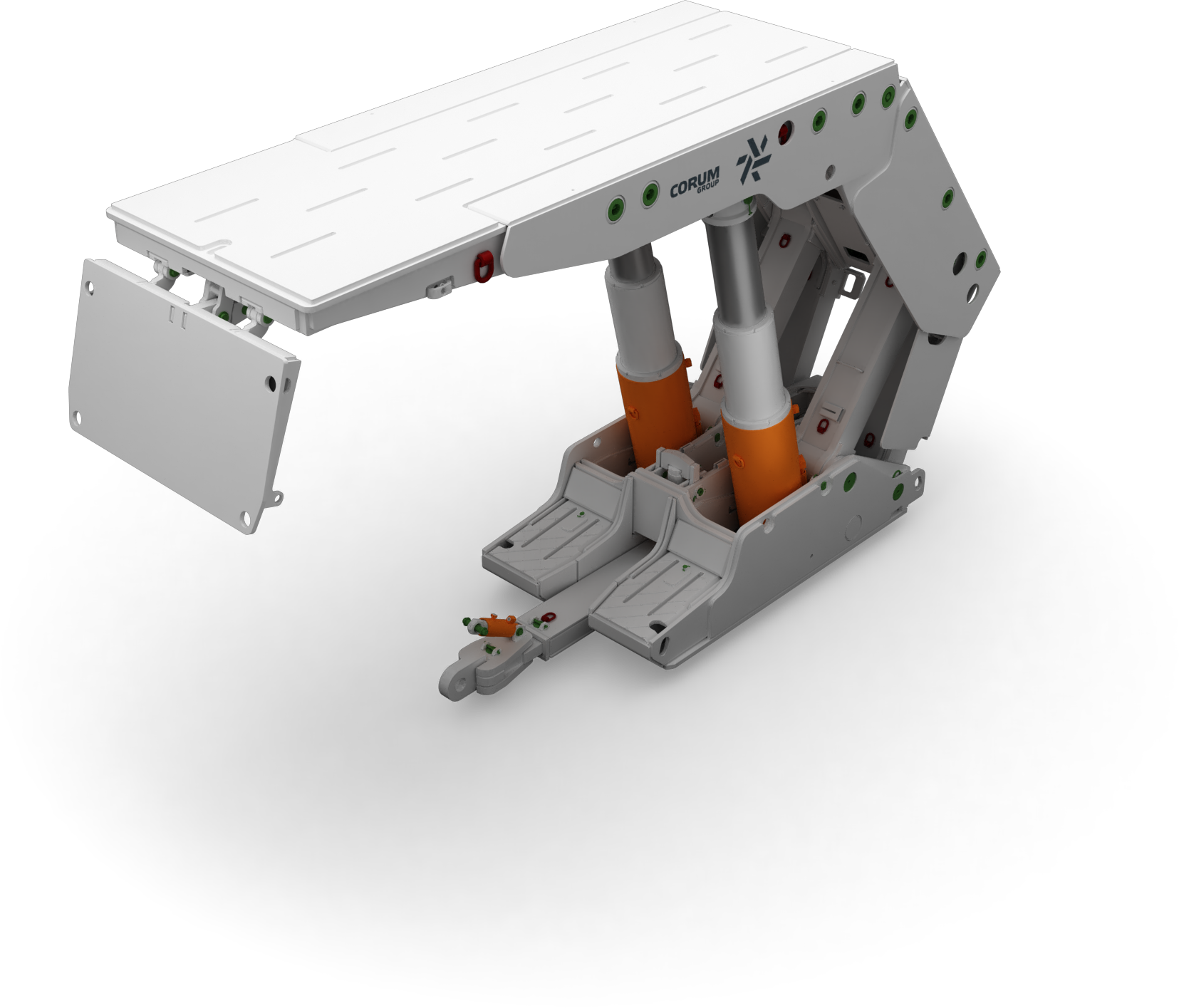

The plant has mastered the production of hydraulic powered roof supports - its main product.

1964

Toretsk Machine-Building Plant was renamed into Druzhkivka Machine Building Plant.

1980s

The plant switched to the manufacture of a new type of hydraulic powered roof supports КД-80, КД-90, МТ, mastered the serial production of winning assemblies for a steep fall АНЩ and АЩМ.

2006

Druzhkivka Machine Building Plant became part of SIC “Mining machines”.

2013

In connection with the rebranding of the management company, the plant received a new name - “Corum Druzhkivka Machine Building Plant”.

2014

The production of a centrifugal fan ВРЦД-4,5СМ, an axial fan ВОД-30М2, suspended equipment of various types, skips, cages, grip blocks, sinking winches ЛПЭП, belt conveyors, pumps НП-200.

2017

Corum Druzhkivka Machine Building Plant became part of the DTEK Energo holding.

2018

The independent production and assembly of the roadheader KPD was mastered, for which only metal works and components were previously manufactured. The plant fulfilled the first order of the Polish mining company Polska Grupa Górnicza (PGG). For the Sośnica mine, 140 newly developed support sections ZRP 15/35 were manufactured.

2019

Corum DrM-BP completed the second order of Polska Grupa Górnicza (PGG). For the Pjast-Ziemovit mine, 135 ZRP 15/35 support sections were manufactured.

2020

Corum DrM-BP continues to expand its product range. The enterprise has mastered the production of winders. First winder Ц-3х2,2АР manufactured and delivered to the customer — Pokrovskoe Maine Administration PJSC “Donetsksteel”.

2021

The plant is actively developing the manufacture of equipment for mine construction. In production, pulleys of various modifications, winches ЛПЭ and ЛПЭП, winder Ц-3х2,2АР. The equipment is designed for construction of the Southern ventilation shaft No. 2 for PJSC “ZZRK”. Entering a new market. Corum DrM-BP has manufactured pilot sections for the largest coal mining company Imbat Madencilik (Turkey).

Facebook

Facebook

YouTube

YouTube LinkedIn

LinkedIn E-mail

E-mail