"Purchasing of a longwall complex is a beneficial solution for miners in terms of output and costs, as this is almost a turnkey longwall", acting director general of Corum Group Mikhail Potapov comments. "For us, as a machine building equipment manufacturer, fulfillment of such a major project signifies a new level of integrated project implementation." Manufacturing of a longwall complex is a special experience requiring individual approach based on client's preferences and equipment operation conditions at a certain longwall.

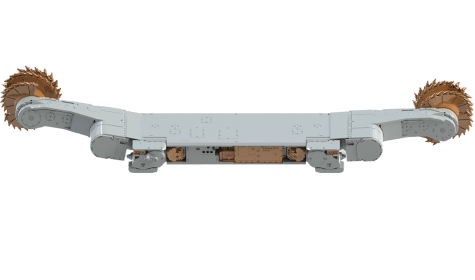

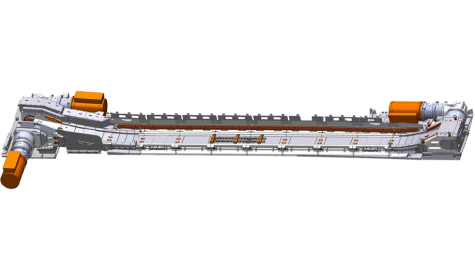

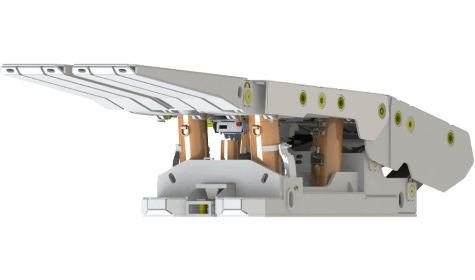

The longwall complex for Sadkinskaya consists of 203 sections of specially designed 3KD90Т roof support, upgraded KDK500 shearer, SPTs230 face chain conveyer and feeder.

It can ensure high level of output of up to 12 thousand tons a day. Thus, in case of continuous operations, it will pay-off within several months. Using this equipment, Sadkinskaya miners plan to produce over 1.5 m tons of high energy anthracite from longwall No. 45 in a year.

"Our mine administration has been using Corum products since long ago: chain conveyers, roof supports, shearers, and their performance is very high and maintenance service is of high quality", Sadkinskaya mine administration director Yury Zuev says. "Thus, when there was a need for a longwall complex, its design was committed to our reliable and well-know contractor – Corum. Now, we have an awesome full cycle machine, as for which we have high expectations."